Although playing with toys is essential for children’s physical and emotional development, toys are often easily discarded once they are no longer considered interesting. As awareness of the risks of plastic use and consumption grows, there is now an increasingly urgent need for people to reconsider the life cycle of plastic toys, from their purchase and repair to their ultimate disposal.

Kokkiri Gongjang produces animal-shaped junk art using scrap toy parts to raise awareness of the dangers of microplastics. This work of art is called School of Salmon.

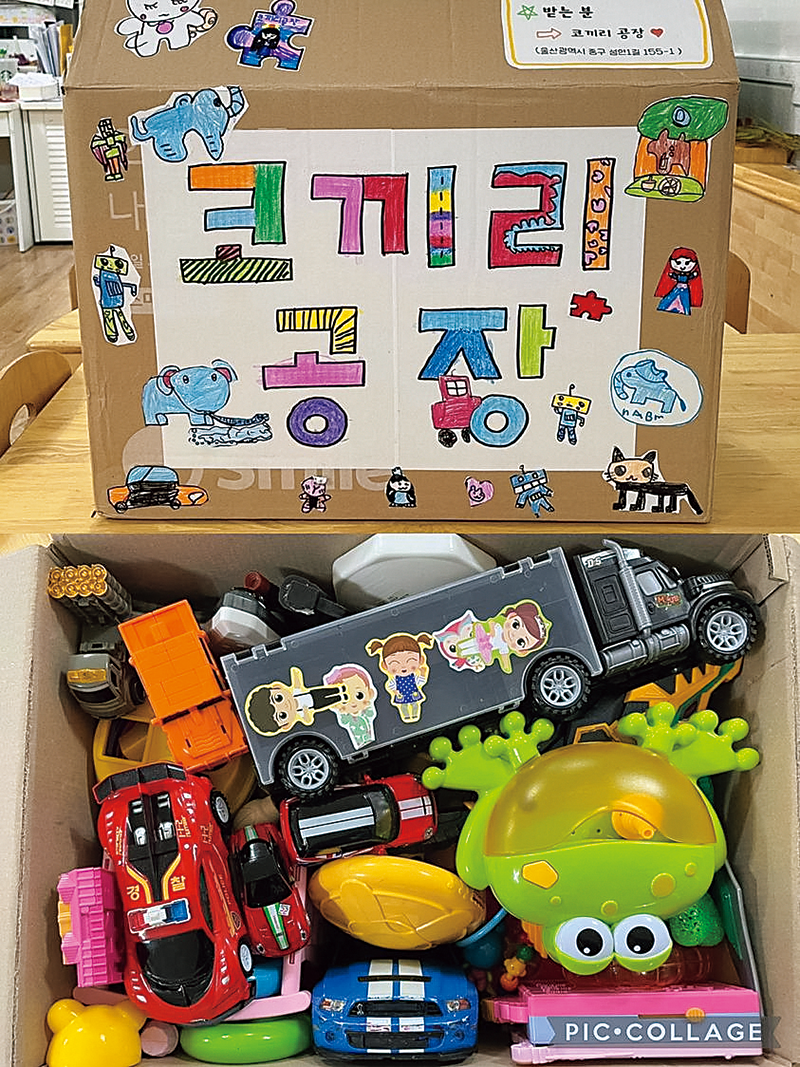

© Elephant Factory

Some parents may often feel the need to give their children anything they ask for. However, amid ever-increasing environmental pollution and the worsening climate crisis, plastic consumption is a growing concern, as is the impact of our lifestyles on the environment: what we eat, drink, and wear. The toys our children play with are no exception.

TOYS TURNED INTO TRASH

Today, most children’s toys are made primarily of plastic. There is now a trend toward using eco-friendly materials for a range of consumer products, but unfortunately, many discarded toys are still classified as general waste. Apart from plastic, they often contain different components such as steel or rubber, used in wires and screws, which means they must either be incinerated or disposed of in landfills. Ironically, if they were made entirely of plastic, they could be partially melted down and recycled.

The reality that most toys cannot be recycled is obviously a serious problem, but so too are the pollutants released during the disposal process. Ultimately, the most sustainable solution is to reduce the number of toys that are discarded by making efforts to get more use out of them. Kokkiri Gongjang, located in Ulsan in southeastern Korea, is a social enterprise that is deeply committed to extending the life cycle of children’s toys.

KOKKIRI GONGJANG’S BEGINNINGS

Donations to Kokkiri Gongjang are classified into repairable and unrepairable toys. Those that can be repaired are distributed to disadvantaged children, while the others are disassembled and either harvested for spare parts or recycled.

© Elephant Factory

Toys are discarded for a variety of reasons. They may break, or children may no longer find them interesting or entertaining. The toys are then typically left unused for a period of time before being thrown out and replaced by new ones. Persuading children to regain interest in old toys can be difficult, but trying to find someone to repair broken ones may prove to be just as difficult. Kokkiri Gongjang founder Lee Chae-jin has firsthand experience with these problems.

While running a toy rental shop, he witnessed how easily toys broke and were discarded. As he looked for toy manufacturers or distributors who would offer repairs, he found that only five percent out of the 600 manufacturers he surveyed did so. It was no wonder then that so many children’s toys were being thrown away. Convinced that this was simply unacceptable, Lee formed a group of individuals who were all skilled at fixing broken s. This “Toy Repair Squad,” the forerunner of Kokkiri Gongjang, initially visited day care centers to repair children’s broken toys.

As a token of gratitude, some of the day care centers donated toys, which were then distributed to other day care centers in need. Kokkiri Gongjang gradually built up a reputation as an organization focused on recycling and sharing toys. Every year, day care centers in Korea call in companies to disinfect their premises as well as the children’s toys. Unlike ordinary disinfection companies, the staff of Kokkiri Gongjang doesn’t just disinfect toys but also fixes any broken ones they find, and the company currently collects over ten thousand toys each year. When these are donated to marginalized children, they represent precious gifts that bring fun and enrichment to their lives.

TOY RECYCLING TO NARROW GAPS

Kokkiri Gongjang employees repairing broken toys.

© Elephant Factory

Children typically play with age-appropriate toys that vary depending on their developmental stage. Children from more affluent families and those who attend well-funded government-run day care centers are able to enjoy a variety of excellent toys, but, unfortunately, the same is not true for children from lower income families. This inspired Lee Chae-jin to go beyond the Toy Repair Squad’s voluntary services and establish the Kokkiri Gongjang enterprise. It repairs and disinfects approximately 70 percent of the collected toys, before distributing them to disadvantaged children. This process not only benefits the environment by reducing plastic waste, but it also aids the development of children’s sensory skills by allowing them to play with a wider variety of toys.

Every month, individuals and organizations across the country donate between 40 and 60 tons of toys to Kokkiri Gongjang. Along the way, the initiative has grown from a small volunteer group to an established social enterprise with locations in Ulsan, Seoul, Incheon, and Gyeonggi Province. This journey and growth have been fueled by a greater awareness of mounting toy waste and its environmental impact, alongside the company’s commitment to social values such as reducing waste and caring for disadvantaged children.

TOY ADVENTURE

![5_[새활용제품] 재생플라스틱으로 만든 ai 자율주행로봇_코봇 (5).png](https://www.koreana.or.kr/upload/editor/20231227161835_bhsxcvxv.png)

The assembly process of “co-bot,” an autonomous AI robot made from recycled plastics, includes elements of coding to stimulate children’s imagination.

© Elephant Factory

The toys processed at Kokkiri Gongjang go through several stages of recycling. First, volunteers carefully fix any repairable toys, which are then donated to other organizations to extend their life cycle. Toys that cannot be fixed, or whose colors have irreversibly faded, are meticulously disassembled. Their non-plastic components, such as wires, screws, and speakers, can then be used as spare parts for other toys. The remaining plastic pieces are sorted by color and material so they can be recycled. Synthetic resin, polypropylene, and polyethylene have different melting points; once these pieces are melted down, they can be used to manufacture completely new products.

Toy plastics have relatively low toxicity and are over ten times more valuable if their components are properly separated. For this reason, Kokkiri Gongjang uses hyperspectral sorting and recycling machines that produce around 300 tons of recycled plastic with 95 percent purity every month. This is used to make items such as flowerpots and key chains, which are then distributed to children. Kokkiri Gongjang also hosts educational events where groups and families can witness its closed-loop recycling process. The experience helps children understand that the toys they no longer play with should not be thrown away but can instead be reused or recycled.

EDUCATIONAL BENEFITS OF RESOURCE RECYCLING

These key rings, part of Kokkiri Gongjang’s eco-friendly product range, were made using plastic flakes from reprocessed plastics.

© Elephant Factory

Children who visit Kokkiri Gongjang can also donate their unwanted toys. Becoming donors instills in them a sense of pride in having done something good. Adding joy to the act of giving, they can then choose to take home one of the toys either repaired or disinfected by Kokkiri Gongjang. Sharing unused toys with those in need, rather than throwing them away or neglecting them, undoubtedly teaches children a valuable lesson. Overall, the Kokkiri Gongjang experience raises awareness of the importance of environmental protection, energy conservation, and caring for children from disadvantaged families.

Yoo Da-mi Writer